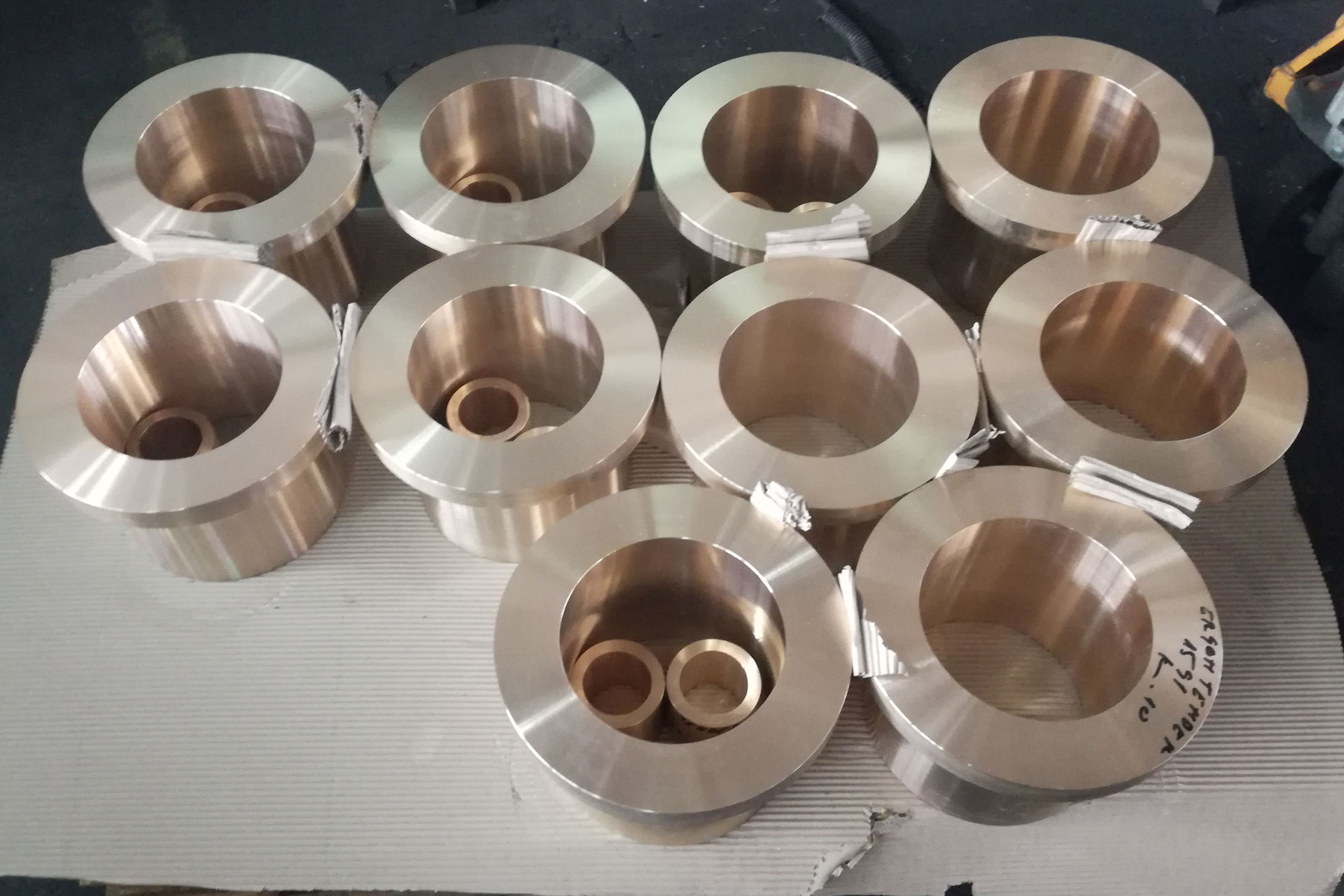

ErgOn S.A. provides a wide range of castings according to the customer’s drawings and specifications. The range varies from simple castings with smooth surfaces up to castings with very fine machining and strict dimension tolerances for every different weight and size.

All castings are delivered after proper heat treatment and any other required treatment e.g. induction hardening on the rolling surface on cast wheels for a longer lifetime.

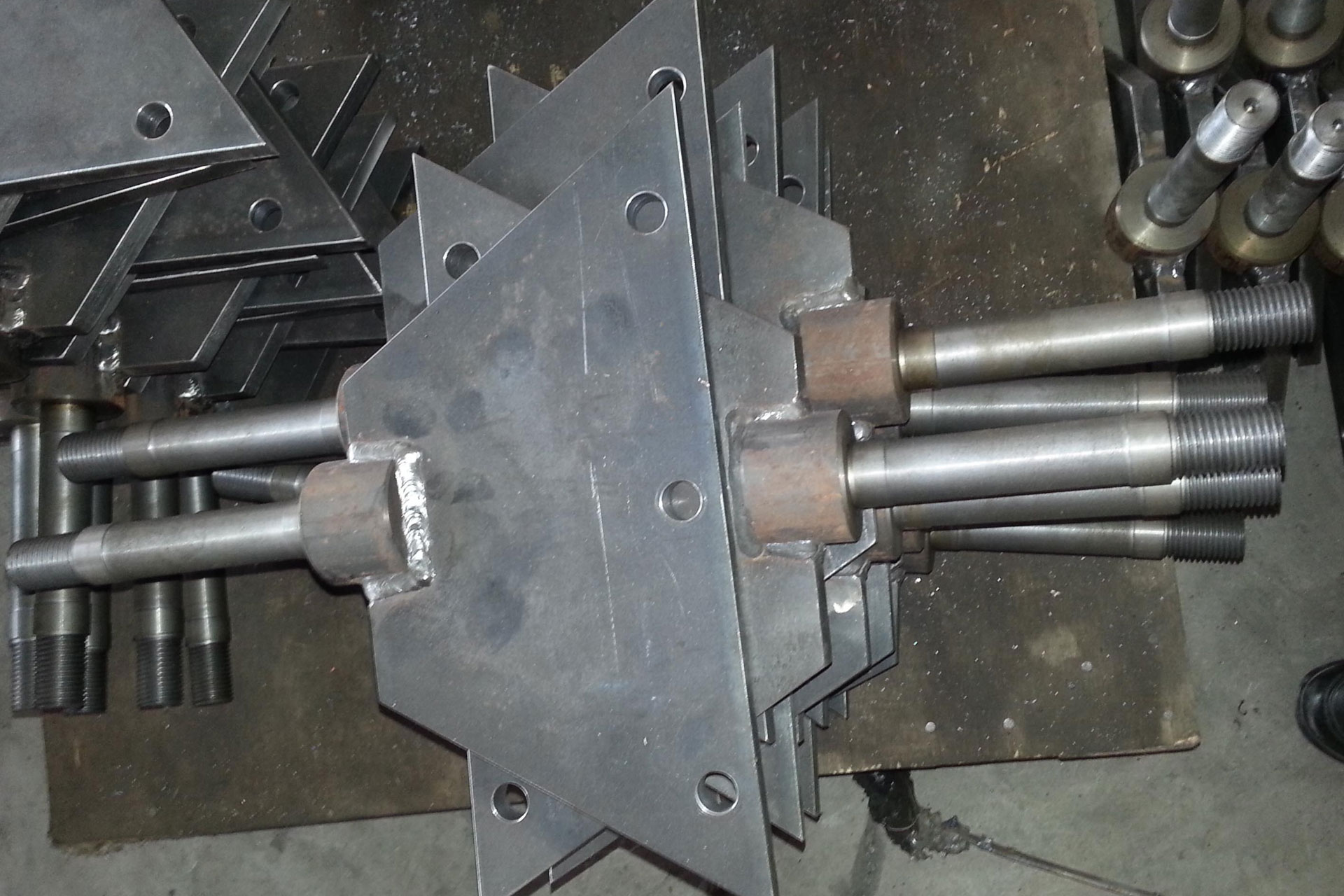

We also take over complex assemblies of castings either by heating up or cooling down the separate parts and machining the assembled piece to the final dimensions tolerances.

A special casting method which is applied by one of our exclusive partners can provide mill hammers with a much longer lifetime!

Our products include castings from <1 kgr/piece up to 120 tons/piece in the following Material Qualities:

- Wear resistant steel-castings quality e.g. G-X120MnCr13, G70CrMn7, SCMNH2 JIS 131, Χ120Mn12, G-X260CrMoCu20, GX300CrMo15 3, NiHARD I, DUCRODAN

- Heat resistant steel-castings quality e.g. G-X30CrSi 6, G-X40CrNiSi27 4, G-X40CrNiSi 25 20

- High tensile strength steel-castings quality e.g. GS-30CrNiMo8, GS-60, GS-42CrMo4, GS-37MnSi5, GS-25CrMo4V, GS-21CrMo4V, GS-52.3, GS-28Mn6

- Austenitic Manganese steel-castings quality e.g. ASTM-A128-75E2, ASTM A 536, 80-55-06, ASTM 532-65T, TYPE I-HC, G-X120Mn12

- Spheroidal graphite iron-castings quality e.g. GGG-30 up to GGG-70

- Iron-castings quality e.g. GG-25

- Brass centrifugal castings quality GZ-CuSn12Pb (2.1061.03)

If required, the castings can be delivered with integrated extensions as defined in ASTM A370/74 which can be cut after delivery for your quality control.